Aerospace Welding Machines

Early pioneers of resistance welding equipment and techniques to spot weld heat-treatable Aluminium Alloys which were becoming popular in airframe construction; we made resistance spot welding machines operating on the ‘stored-energy’ system. These could produce the very high secondary currents needed to spot weld the very low-resistance materials and at the same time apply a very fast forging force to consolidate the weld nuggets and satisfy the demanding standards required for airborne fabrications.

These machines fulfilled their objectives, but had limitations of weld duration, so we introduced the world-famous Sciaky three-phase MODU-WAVE machines which extended the range of materials and thicknesses that could be welded to the same high standards. Connecting across three supply phases and producing Direct Current for welding and subsequent heat-treatment. The secondary current waveform can be modulated to have a slope-in to weld level followed by a decay to provide a controlled cooling of the weld nugget. Allied to this is a virtually frictionless application of weld and forge force to the electrodes eliminating internal weld defects.

These machines will produce welds to the quality demanded by AWS DF17.2 (formerly MIL 6858D).

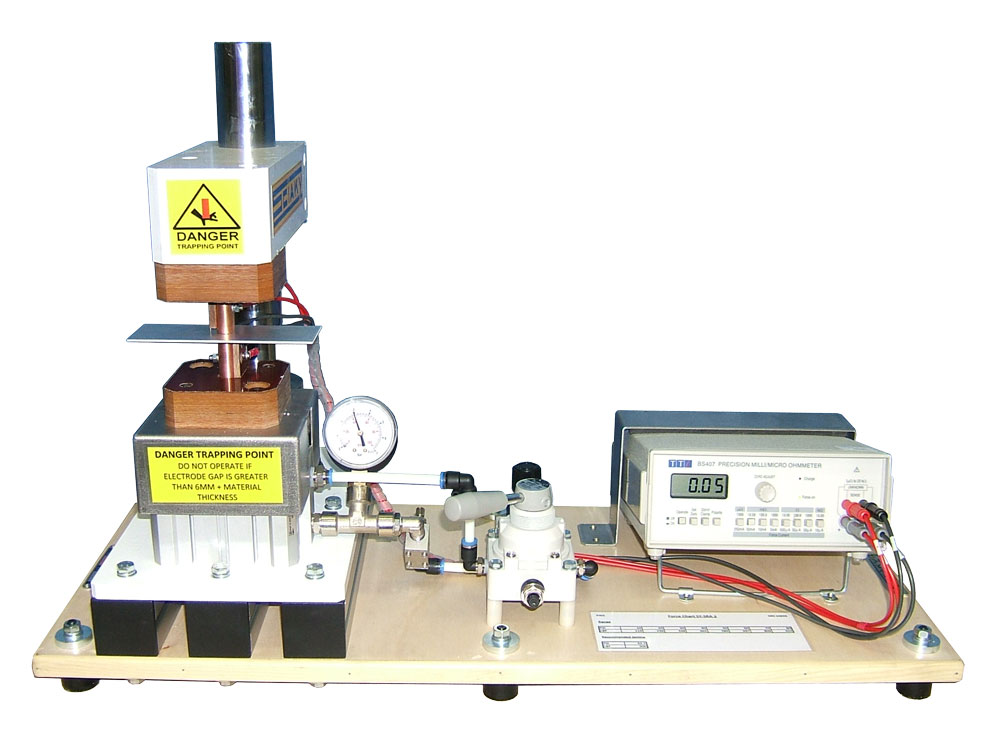

Surface Resistance Analysis

Sciaky also supply the SY-SRA2 Surface Resistance Analyser to measure the surface resistance of Light Alloys prior to welding; this ensures that the surface oxides have been satisfactorily removed by the cleaning process.

Sciaky provide full support in the form of:

- Routine ServiceCalibration

- Qualification

- Service

- Training

Contact us for further information as .pdf documents: Aero Brochure, Aero spot welders, Aero seam & roll-spot welders, SY-SRA2 Surface Resistance Analyser

New or Works Rebuilt

Resistance welding machines operating under several systems are available for aerospace quality welding.

- Three-phase Modu-wave; known as ‘frequency converters’: direct weld current. The only machines qualified to weld Heat Treatable Light Alloys to AWS DF17.2 Class A standard.

- Three-phase hexaphase: secondary rectification: direct welding current

- Three-phase Mid Frequency: direct weld current

- Single phase DC: secondary rectification: DC weld current

- Single-phase AC: AC weld current

We can indicate the optimum type of resistance welding machine if we know:

- All materials to be welded and their minimum/maximum thicknesses

- Throat depth of machine and any special accesses required